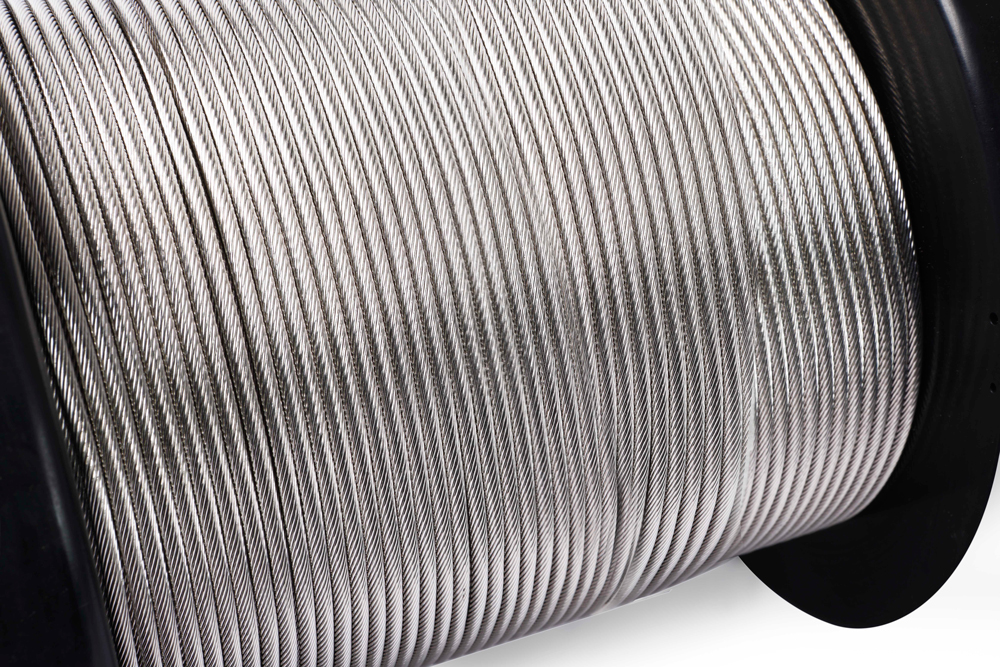

Stranded resistance wires are used to construct Ceramic Pad Heaters by insulating it in high alumina ceramic interlocking beads.

Different types of stranded wire:

| ALLOY | Total Dia. (mm) |

STRAND CONSTRUCTION (MM) | RESISTANCE (Ohms/M) |

STOCK OPTIONS | |

| No. of strands x size | King wire size | ||||

| NiCr 80/20 | 2.8 | 19 x 0.55 | 0.55 | 0.26 | On Request |

| NiCr 80/20 | 2.67 | 19 x 0.523 | 0.574 | 0.28 | Ready Stock |

| NiCr 80/20 | 2.76 | 37 x 0.385 | 0.508 | 0.27 | On Request |

| NiCr 60/16 | 2.67 | 19 x 0.523 | 0.574 | 0.29 | Ready Stock |

| NiMn2 | 2.87 | 19 x 0.61 | 0.71 | 0.02 | Ready Stock |

**We can also supply core heating wire welded with cold tail wire and 60 A male camlock for 60V and 80V pad heaters.

Nichrome Wire:

Nichrome wire, is a composite of 80% nickel and 20% chrome, creating a tough hard to bend wire, with a high temperature tolerance, this alloy has won universal acceptance among users of metallic resistance materials & it is used for a range of applications, including foam cutting, interior ribbing for clay models, heating elements and much more.

It is an excellent choice for heating elements operating at temperatures up to 1100°C, it can be welded with ease to the required components, as another option of joining.

Specification:

Gauge: 8SWG, 10SWG, 12SWG, 14SWG and 16SWG